Protective 20mm To 50mm GI Conduit Pipe With High-Performance Plastic Film Package

Product Description:

GI Conduit Pipe

GI Conduit Pipe is a type of galvanized steel conduit pipe used in electrical wiring systems. It is a type of pipe that is used to protect and route electrical wires in buildings, construction sites, and industrial facilities. The GI Conduit Pipe is made from high quality galvanized steel which is known for its durability and strength. It is designed to withstand harsh environmental conditions, making it an ideal choice for outdoor installations.

The GI Conduit Pipe comes in two surface options: pre-galvanized and hot-dipped galvanized. Pre-galvanized GI Conduit Pipe has a layer of zinc coating on its surface, making it resistant to corrosion and rust. It is suitable for indoor installations where it is not exposed to harsh weather conditions. On the other hand, hot-dipped galvanized GI Conduit Pipe has a thicker layer of zinc coating, making it suitable for outdoor installations. The hot-dip galvanizing process provides a more durable and long-lasting surface, making it the preferred choice for industrial and outdoor applications.

The GI Conduit Pipe is available in different sizes and lengths to meet various electrical wiring needs. It can be easily cut and bent to fit different installation requirements. This makes it a versatile and flexible option for different types of electrical projects.

In addition to its standard features, the GI Conduit Pipe also offers OEM and ODM services. This means that the product can be customized according to the specific requirements of customers. Whether it is a different size, length, or surface treatment, the GI Conduit Pipe can be tailored to meet the needs of different projects.

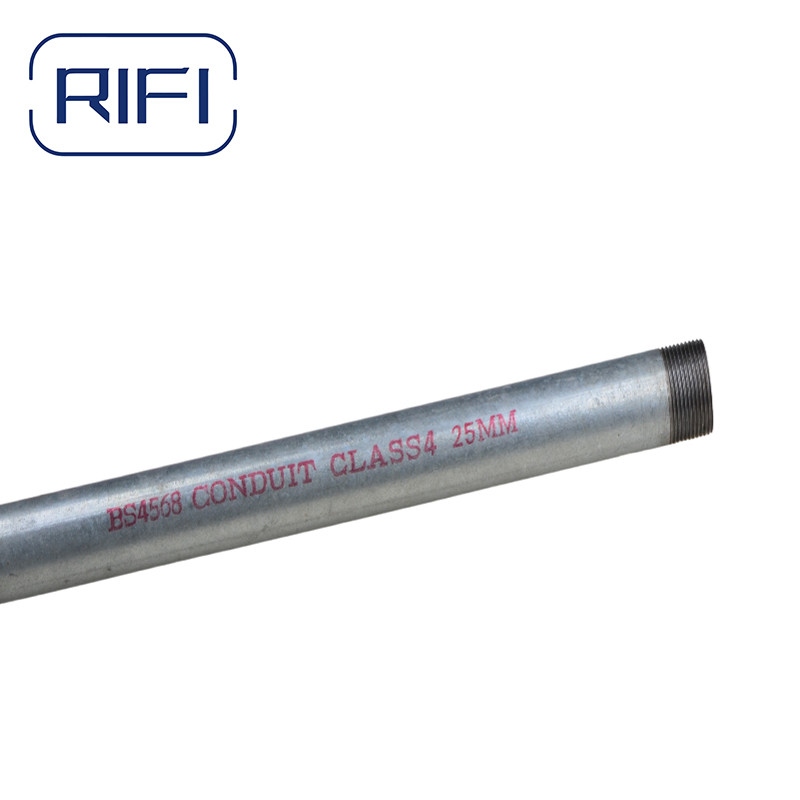

The surface treatment of the GI Conduit Pipe is an important aspect to consider. The hot-dip galvanizing process provides a high level of protection against corrosion and rust, making it suitable for harsh environments. It also gives the pipe a smooth and polished finish, enhancing its appearance.

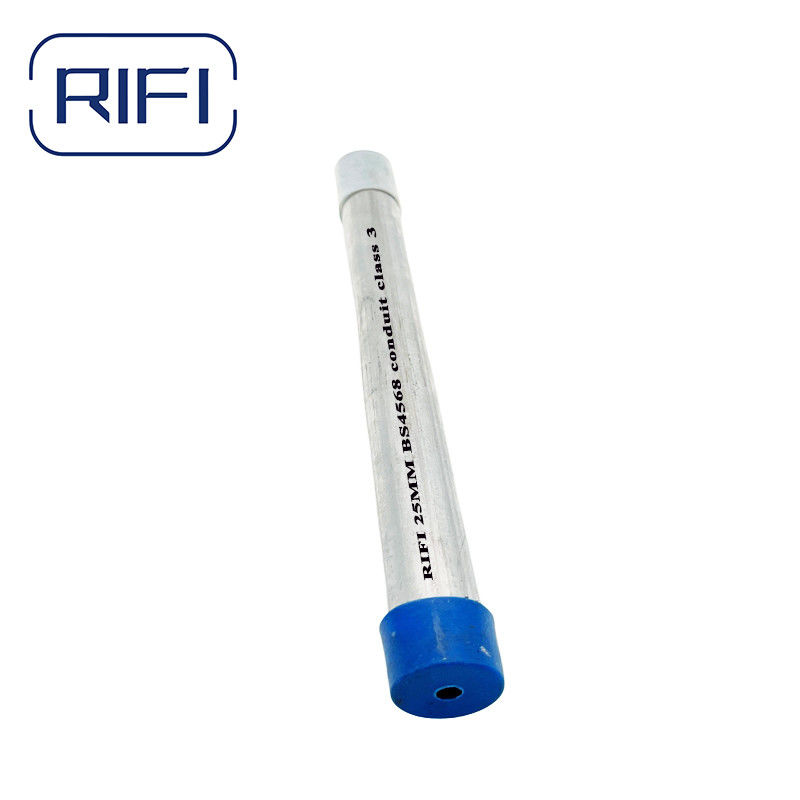

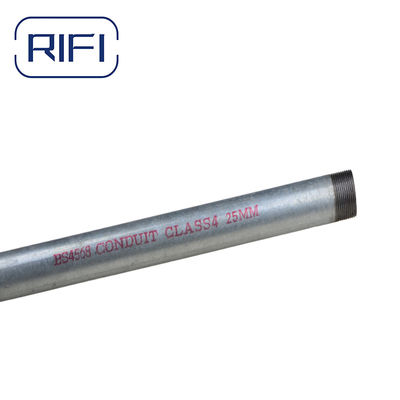

Lastly, the GI Conduit Pipe is available in two different classes: Class 3 (pre-galvanized) and Class 4 (hot-dipped galvanized). The Class 3 GI Conduit Pipe is ideal for indoor installations, while the Class 4 GI Conduit Pipe is suitable for outdoor and industrial applications. Both classes offer excellent protection and durability, making the GI Conduit Pipe a reliable choice for electrical wiring projects.

Key Features:

- High quality galvanized steel material

- Available in pre-galvanized and hot-dipped galvanized surfaces

- Customizable with OEM and ODM services

- Hot-dip galvanizing for superior surface protection

- Available in Class 3 and Class 4 options

- Versatile and flexible for different installation needs

In conclusion, the GI Conduit Pipe is a durable and reliable product that offers excellent protection for electrical wiring systems. Its high-quality material, customizable options, and superior surface treatment make it a top choice for both indoor and outdoor installations. With its strong and sturdy construction, the GI Conduit Pipe is a must-have for any electrical project.

Technical Parameters:

| Technical Parameters |

GI Conduit Pipe |

| Features |

High Strength, Corrosion Resistance, Easy To Install |

| Feature |

Protective |

| OEM/ODM |

Available |

| Thickness |

1.2mm-1.6mm |

| Surface Treatment |

Hot-dip Galvanized |

| Approved |

BS4568 BSEN61386 |

| Class |

Class 3 (Pre-galvanized) or Class 4 (Hot Dip Galvanized) |

| Finish |

Hot-dip Galvanized or Pre-galvanized |

| Color |

Silver |

Packing and Shipping:

Packaging and Shipping for GI Conduit Pipe

GI Conduit Pipe is typically packaged and shipped according to the customer's specific requirements. However, the standard packaging and shipping methods for this product are as follows:

Packaging:

- GI Conduit Pipe pack as plastic bag to prevent scratches and damage during transit.

- The pipes are then packed in bundles, with each bundle containing a specific number of pipes based on the customer's order quantity.

- The bundles are then secured with strapping or banding to ensure they remain intact during shipping.

Shipping:

GI Conduit Pipe is typically shipped via sea .For sea freight, the pipes are loaded onto shipping containers and transported to the nearest port.

Overall, great care is taken in packaging and shipping GI Conduit Pipe to ensure that it reaches the customer in excellent condition and on time.

FAQ:

- Q: What is the brand name of this product?

A: The brand name is RIFI.

- Q: What are the model numbers for this product?

A: The model numbers are BS4568 and BS31.

- Q: Where is this product manufactured?

A: This product is manufactured in TIANJIN.

- Q: Does this product have any certifications?

A: Yes, it is certified with ISO.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!